|

FOR IMMEDIATE RELEASE

May 8, 2007

CONTACT:

Missy Corley

(301) 405-6501

mcorley@umd.edu

COLLEGE PARK, Md.—Influenza virus H5N1, which caused the recent outbreak of avian flu, may have a new enemy. COLLEGE PARK, Md.—Influenza virus H5N1, which caused the recent outbreak of avian flu, may have a new enemy.

Researchers at the University of Maryland's A. James Clark School of Engineering have created a "virus sponge" that could filter a patient's blood in a process similar to kidney dialysis, removing the virus from the patient's body. The concept could also be used to make vaccine production more efficient and in a pill to reduce glucose levels in diabetics, among other applications.

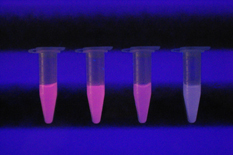

The virus sponge is based on a technology called molecular imprinting. In molecular imprinting, researchers stamp a molecule's shape into a substance (in this case, a hydrogel—a material that looks like a powder when dry; and like Jell-O when wet). When the specific molecule filters through the hydrogel, it fits in the imprint hole and is trapped.

The research group of Peter Kofinas, a professor in the Clark School's Fischell Department of Bioengineering, is the first to apply molecular imprinting to the capture of viruses, and to show that this approach is possible using an inexpensive hydrogel.

Kofinas's team has so far used this technique on plant viruses and Human Parvovirus B19, which causes "fifth disease" in babies, and has now begun work on the H5N1 influenza virus.

"This new technology could be integrated into hospitals and healthcare centers at minimal cost," according to Kofinas. Modifying existing dialysis machines to include the virus sponge technology would be relatively simple, he said.

"This virus removal device can be used the same way as a kidney dialysis machine," Kofinas continued. "If you have a viral infection, you can go to the hospital and have your blood cleaned of that virus."

While a new vaccine must be developed each year for the strain of influenza that is expected to be the most potent, a hydrogel can be imprinted as a universal filter for all flu strains. However, to achieve better performance, a hydrogel filter can also be produced to catch a particular strain of the virus.

The molecular imprinting process has many applications beyond trapping viruses.

"Applying the technology to a drug or food additive could contribute to the dietary freedom of those who suffer from type II diabetes," Kofinas said.

A pill containing the hydrogels could be developed to remove excess sugars when taken with food, thus helping diabetics regulate their diet, Kofinas explained. The hydrogels would work within the small intestine to remove glucose prior to absorption into the blood stream.

Drug manufacturers could use the hydrogel filters in vaccine production. Pharmaceutical companies use viruses to create the vaccines that fight them. Hydrogels could be used to strip the virus out of the finished medication—a process that is currently very time-consuming and expensive.

Another potential application is to use the material as a filter in masks for those needing protection in case of biological warfare or other harmful biological agent exposure.

Kofinas has filed a patent on this technology. Currently, he is collaborating with researchers at the National Institutes of Health on how to use the hydrogels to clean human viruses out of blood.

Advances in this area could help ensure a safer blood supply by allowing for the low-cost removal of viruses like hepatitis and HIV from donor blood.

Kofinas is also associate chair and director of graduate studies in the Fischell Department of Bioengineering. His graduate students, Linden Bolisay, Brendan Casey, Angela Fu and Daniel Janiak, continue to contribute to this research.

NOTE TO EDITORS:

The hydrogel material can be seen on camera.

More Information:

Peter Kofinas' Research Projects

About the A. James Clark School of Engineering

The Clark School of Engineering, situated on the rolling, 1,500-acre University of Maryland campus in College Park, Md., is one of the premier engineering schools in the U.S.

The Clark School's graduate programs are collectively the fastest rising in the nation. In U.S. News & World Report's annual rating of graduate programs, the school is 15th among public and private programs nationally, 9th among public programs nationally and first among public programs in the mid-Atlantic region. The School offers 13 graduate programs and 12 undergraduate programs, including degree and certification programs tailored for working professionals.

The school is home to one of the most vibrant research programs in the country. With major emphasis in key areas such as communications and networking, nanotechnology, bioengineering, reliability engineering, project management, intelligent transportation systems and space robotics, as well as electronic packaging and smart small systems and materials, the Clark School is leading the way toward the next generations of engineering advances.

Visit the Clark School homepage at www.eng.umd.edu.

###

|

|

|

E-Mail our media staff or call:

(301) 405-6501 |

| |

|

| |

Click the image below for the high-res version.

Credit—Clark School of Engineering - University of Maryland. |

|